In recent years, the term “Digital Twin” has gained significant attention across various industries, from manufacturing to healthcare. A digital twin refers to a virtual replica of a physical entity—whether it’s a product, system, or even a person. This concept is rapidly becoming a game-changer in the fields of simulation, modeling, and data analytics, providing new ways to monitor, predict, and optimize performance in real-time.

What Are Digital Twins?

A digital twin is a dynamic, digital representation of a physical object or system. It uses real-time data from sensors, devices, and IoT networks to create an accurate model of its counterpart. The digital twin is continuously updated as it receives data, allowing users to simulate, analyze, and predict the behavior of the physical entity without any direct intervention.

For example, a digital twin of a jet engine can collect and analyze real-time performance data to identify potential maintenance needs, forecast failures, and optimize fuel efficiency.

How Do Digital Twins Work?

Digital twins operate through the integration of multiple technologies, including IoT sensors, big data analytics, artificial intelligence (AI), and cloud computing. Here’s a step-by-step breakdown of how they function:

- Data Collection: Sensors embedded in the physical object collect a variety of data—temperature, pressure, humidity, speed, and more.

- Data Transmission: This data is transmitted to the cloud or an edge computing system.

- Data Analysis: AI and machine learning algorithms process the data to create a real-time digital model of the object.

- Modeling and Simulation: Engineers and analysts use this model to run simulations, predict outcomes, and optimize operations.

- Action and Optimization: Based on the insights gathered from the digital twin, real-world processes can be adjusted for greater efficiency, performance, and safety.

Applications of Digital Twins

1. Manufacturing and Industry 4.0

In manufacturing, digital twins are revolutionizing the way products are designed, tested, and optimized. They enable engineers to create virtual prototypes and simulate performance under various conditions before physical production begins. This minimizes costly errors and accelerates the development process.

- Predictive Maintenance: Monitoring equipment health and identifying potential failures before they occur.

- Process Optimization: Simulating different production scenarios to find the most efficient methods.

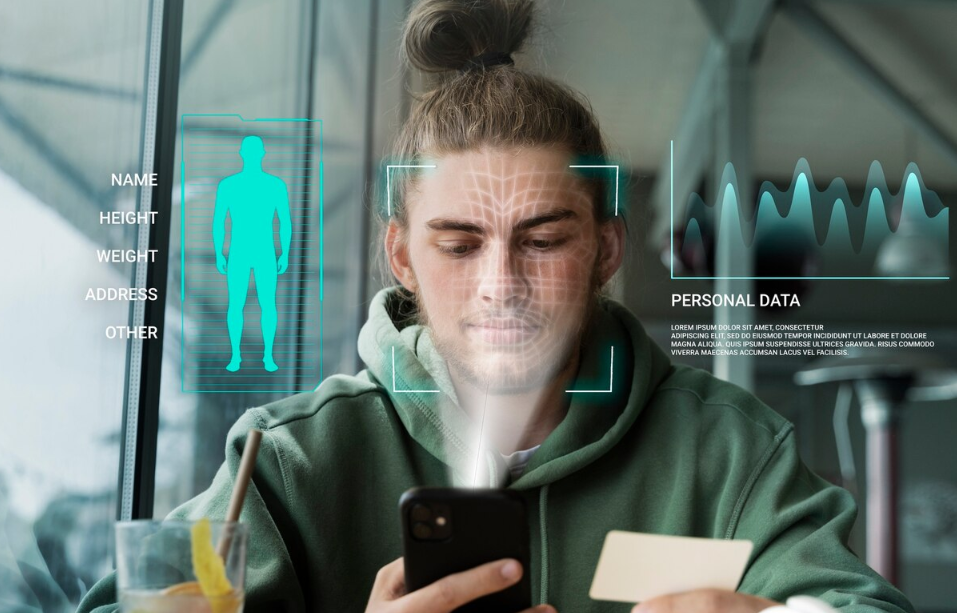

2. Healthcare and Medicine

Digital twins are beginning to make waves in healthcare, where they are used to simulate individual patients’ health profiles. By creating a digital twin of a patient’s body or specific organs, healthcare providers can model the effects of treatments, predict recovery times, and personalize care plans.

- Personalized Medicine: Tailoring treatments based on a virtual model of a patient’s body.

- Surgical Simulation: Simulating surgeries on digital twins to train surgeons or plan complex procedures.

3. Smart Cities and Urban Planning

Urban planners are using digital twins to simulate entire cities, creating “living models” that reflect the current state of infrastructure, traffic, utilities, and public services. This data allows for better planning, real-time monitoring, and predictive insights.

- Traffic Management: Optimizing traffic flow and reducing congestion based on simulated scenarios.

- Energy Management: Optimizing energy consumption across buildings and transportation networks.

4. Automotive and Aerospace

The automotive and aerospace industries are adopting digital twins to design, test, and monitor complex systems, such as vehicles and aircraft. These virtual models help identify potential design flaws, test performance under different conditions, and streamline maintenance.

- Vehicle Design: Testing new vehicle designs in a simulated environment before building prototypes.

- Flight Simulations: Modeling aircraft components and systems to improve safety and performance.

Benefits of Digital Twins

1. Enhanced Decision Making

By providing real-time data and simulations, digital twins allow organizations to make informed decisions based on accurate, up-to-date information. This leads to smarter, more efficient processes across all industries.

2. Cost Reduction

The ability to simulate systems before physical implementation allows businesses to reduce errors, avoid costly repairs, and optimize resource allocation, ultimately saving money in the long run.

3. Predictive Insights

Digital twins allow for predictive analytics, helping businesses anticipate failures, malfunctions, and inefficiencies. This helps organizations plan for maintenance, prevent downtime, and extend the lifespan of assets.

4. Improved Product Design and Innovation

With digital twins, companies can test new designs, features, and processes in a virtual environment, speeding up innovation and product development cycles.

Challenges of Digital Twins

While the potential of digital twins is immense, there are some challenges to consider:

- Data Security and Privacy: As digital twins rely on vast amounts of data, ensuring the security and privacy of this information is crucial.

- Integration Complexity: Integrating digital twin technology with existing systems and infrastructure can be technically challenging and costly.

- Data Quality: For digital twins to be effective, the data collected must be accurate, timely, and comprehensive. Inaccurate data can lead to faulty simulations and misguided decisions.

The Future of Digital Twins

The future of digital twins is bright, with applications expanding across nearly every sector. As technology continues to evolve, we can expect digital twins to become more sophisticated, with enhanced AI and machine learning capabilities. Key trends include:

- AI-Driven Automation: Digital twins integrated with AI will enable fully autonomous decision-making and optimization in real-time.

- Edge Computing: More processing power at the edge will allow for faster, more efficient digital twin operations.

- Interconnected Digital Twins: We may soon see networks of interconnected digital twins, creating a digital ecosystem that spans industries, cities, and countries.

Conclusion

Digital twins represent a significant leap forward in the way we simulate, model, and optimize the physical world. From manufacturing and healthcare to smart cities and beyond, the potential applications of this technology are vast. As industries continue to harness the power of digital twins, we can expect smarter, more efficient, and more personalized systems that can predict, optimize, and enhance our daily lives.